As diesel engines have evolved, and vehicle emissions have been monitored heavily, manufacturers have been employing more and more emissions control devices, to better protect the environment and reduce the unsightly ‘black clouds’ that are renowned with older diesel vehicles.

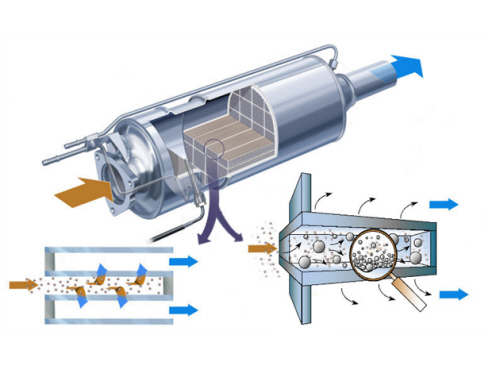

One of these systems is the Diesel Particulate Filter (DPF) which sits in the exhaust system and filters harmful carbon particulates produced in the combustion cycle, preventing these particles from being released into the atmosphere.

What is a diesel particulate filter?

A diesel particulate filter (DPF) is a filter that captures and stores exhaust soot (some refer to them as soot traps) in order to reduce emissions from diesel cars and trucks. The filter is designed to deliver an 80% reduction in diesel particulate and soot emissions, it does this by trapping the particles in the filter itself. But because they only have a finite capacity, this trapped soot periodically has to be emptied or ‘burned off’ to regenerate the DPF.

This regeneration process cleanly burns off the excess soot deposited in the filter, reducing the harmful exhaust emission and helps to prevent the tell-tale black smoke you used to see from diesel vehicles, particularly when accelerating.

First fitted to diesel vehicles since 2007, the DPF has been causing confusion and, in many cases, expensive repair bills for drivers, due to lack of knowledge about the system.

The engine control unit (ECU) monitors the saturation level inside the filter, and when it reaches a certain percentage, increases the temperature inside the exhaust to ‘burn off’ the particles.

The procedure for your vehicle’s DPF regeneration process, as well as all the information on the system, will be located in your owner’s manual.

There are three different types of DPF regeneration methods:

Passive Regeneration

Active Regeneration

Forced Regeneration

Passive Regeneration

Passive regeneration takes place automatically, with no warning lights coming up on the dashboard. It mainly occurs on highways, when the vehicle speed and exhaust temperature is high. Depending on how the vehicle is used however, this may not be possible. Stop-start driving, or around town trips will not allow the exhaust to get up to temperature to carry out this regeneration.

Active Regeneration

Once the ECU reads the soot loading has reached a certain limit (usually around 45%), it will instigate what is known as post combustion fuel injection. This procedure injects a small amount of fuel into the engine after the main combustion cycle, to increase the temperature in the exhaust and trigger the regeneration process.

The ECU will usually give a warning on the dashboard to alert the driver that the regeneration process is in progress.

Depending on your vehicle, you will need to keep your vehicle over a certain speed and engine RPM until the warning has been turned off.

The procedure should be covered in your owner’s manual, but a rough guide is to keep the engine speed over 2,000RPM and the vehicle speed over 40mph.

Depending on the saturation level, this process may take anywhere from 5 minutes up to 30 minutes.

You may notice increased fuel consumption, the cooling fans running constantly and a slight acrid smell from the vehicle during this period. This is normal, as the exhaust temperature reaches over 600 degrees to burn off the particles.

If the process is interrupted and the regeneration cannot be completed, the ECU will activate ‘Reduced Power Mode’ or ‘Limp Home’ mode. This will limit power to prevent any damage to the engine or exhaust systems. The DPF and Engine warning lights will both come on when the vehicle enters this mode.

Forced Regeneration

If the DPF and Engine warning lights come on, the final regeneration will need to be completed. This is known as a Forced Regeneration. The vehicle will need to be driven carefully or towed down to a repair facility to have the DPF manually regenerated.

This process is carried out by connecting a diagnostic scan tool to the vehicle and forcing the vehicle to carry out a regeneration. This can be a costly exercise as the oil and oil filter will require changing after the service has been completed. This is due to the extra fuel that is added after the combustion cycle, as some of it works its way into the sump and dilutes the oil.

Depending on how blocked the DPF is, it may be the case that these regeneration procedures cannot clean the DPF completely. The only way to carry out complete removal of particles is to remove the filter from the vehicle, and have it professionally cleaned, and or replace the filter altogether. This is an extremely expensive exercise, as replacement DPF units can cost many thousands of dollars!!

What can prevent normal regeneration taking place?

- Frequent short journeys, such as stop-start city driving, that do not allow the engine to reach correct operating temperature

- Using the wrong oil type – DPF equipped vehicles require oil of a ‘low Ash, low Sulphur’ grade, to prevent excess build-up occurring

- An issue with another emissions control device, such as the exhaust gas recirculation (EGR) system, or a problem with the air inlet or fuel systems

- Low fuel level – most vehicles will not carry out a regeneration cycle if the fuel level is under ¼ of a tank

- Overdue service interval – low oil quality or level will prevent regeneration from occurring

- Engine warning light on – a warning light or a diagnostic trouble code stored in the ECU may prevent regeneration

When purchasing a diesel vehicle, it is important to check and see if it is fitted with a Diesel Particulate Filter, and whether your driving style will allow the system to be used to its full potential, or it will cause you headaches and expensive repairs in the long run.

If you own Diesel truck or are considering purchasing one, feel free to send us an email with any questions you may have.